A loading bay is a place where people work together efficiently to ensure that trucks are loaded and unloaded as quickly as possible. But security also plays a major role due to the increasing flow of goods. By using a dock shelter you can guarantee both efficiency and safety. A dock shelter is intended to provide a good seal between the lorry and the building's façade. When a dock shelter no longer functions properly, it complicates the logistics process. This is why regular maintenance is important. However, maintenance depends on the type of dock shelter; cushions, flaps or inflatable shelter. It is best to have maintenance carried out by a specialised company such as Loading Systems. Nevertheless, there are a number of things you can check yourself to ensure the daily safety of your employees and the efficiency of the logistics process.

1. Test all functions once a week

To ensure that the dock shelter works properly, it is important to check all functions once a week. Do this even if the dock shelter is not in use. This only applies to electrically operated shelters, such as the inflatable dock shelter.

How do you perform the check? In short, run the dock shelter program several times.

2. Check your dock shelter monthly

To ensure safety on the loading bay, it is necessary to check the entire shelter once a month. Check the following:

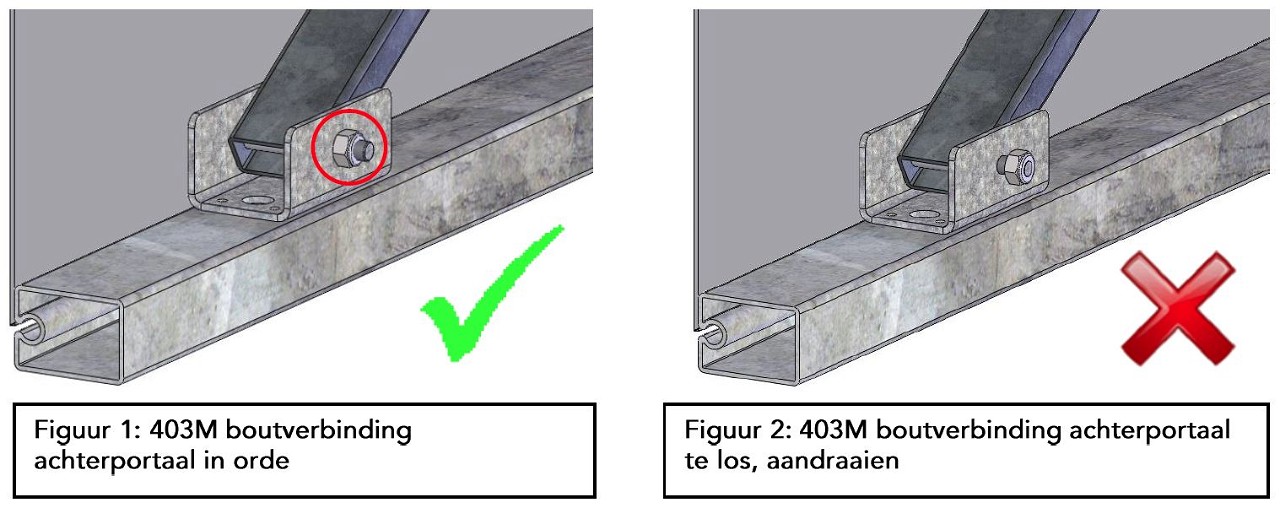

- All mounting and fixing points

- The voltage of the conductor cables

- The protective strips, cushions and fabric for damage or leakage

- All tension rubbers

3. Train your staff

Make sure your staff are aware of how the dock shelter should be checked. In this way, everyone can see if one of the safety devices is damaged and sound the alarm in time. In addition, it is important to take into account issues such as operation, distance to the truck and the use of objects.

Do you have a problem? This is how you solve it!

The dock shelter may not function properly. This may be due to an unclear reason or the shelter not responding when operating the control box. In this situation, you should do the following:

- Check that all safety options function properly. These include wheel chocks or vehicle detection. It could be that the operation of the shelter is being blocked by the malfunctioning of a safety option.

- Check whether there are any obstacles in the movement area. Remove them if necessary.

- Check that the wall plug is inserted into the wall socket, only in the case of electrical dock shelters.

If the above solutions have not solved the problem, our service engineers are ready to assist you. Do you have a malfunction that you cannot resolve yourself? Report it here!

Do you want to avoid downtime? Preventive and periodic maintenance

In addition to the above tips for maintaining your dock shelter(s) yourself, we recommend that preventive and periodic maintenance be carried out by a specialist service party. Not only is it a legal requirement to have your loading bay inspected once a year, it also ensures that downtime is prevented. We distinguish between preventive and periodic maintenance.

Preventive maintenance

A poorly maintained dock shelter can complicate the loading and unloading process, or even bring it to a complete standstill. Therefore, in addition to the maintenance tips mentioned above, we recommend preventive maintenance, for example with our CPIT (change parts in time) programme. In this way, you not only ensure safety at the loading bay, but you also ensure that the functionalities and/or classifications of the dock shelter are maintained.

Depending on the type of dock shelter, parts need to be replaced. In the case of a flaps shelter, it is advisable to replace the rubbers when they are 50% worn. This prevents the shelter from malfunctioning. The rubbers may become worn due to friction between the truck and dock shelter or due to extreme weather conditions such as strong winds. The result? When the rubbers are damaged, considerably more energy can be lost. Also, the top flap may tear if the rubbers are not in place.

With an inflatable dock shelter, we recommend replacing the guide cables every 3 years to extend the service life of the dock shelter. This is to prevent the dock shelter from coming to a standstill. The frequencies listed are indicative, it may be that the parts need to be replaced sooner in active use.

Periodic maintenance

Depending on the type of dock shelter, you must have your shelter inspected once a year by authorised service technicians. This is important, for example, for the inflatable shelter During this maintenance, the shelter is checked for proper functioning and any defects and faulty parts. The technician checks all mechanical and electrical components.

Want more information about how our technicians carry out maintenance? Feel free to contact us!

In the case of the flaps dock shelter, it is not mandatory to have an annual inspection carried out by an authorised service company. Nevertheless, we always recommend this. Why? This way you know that all safety devices are undamaged and work properly. It is also possible to act quickly if one of the facilities is damaged. It is very important to always use the dock shelter as directed.

Loading Systems as your service party – We take care.

Maintenance is crucial, not only on your dock shelter but on your entire loading bay. With proper maintenance, you can extend the life of your products, ensure safety on the loading bay and increase efficiency. Would you like to have one partner for all your maintenance? Loading Systems is here for you!

The benefits of a Loading Systems service agreement:

- Brand-independent service

- Skilled technicians

- 24/7 availability

- Avoid downtime

- No surprise costs