COVID-19 has changed most things in our life… the market, the customer, the business world not to mention our personal lives.

So how do you make future plans when everything is so uncertain? This was the question Loading Systems asked themselves. As it turns out the answer was by keeping close to their customers, listening and adapting to their needs and producing the right product at the right time for them!

Loading Systems

Family-owned Loading Systems was founded in 1965. With modest steps, the loading specialist from Lelystad has grown into an established name with branches throughout Europe, the Middle East and Asia. A wide range of customers such as Amazon, Ikea, Next, Ocado and BMW have come to appreciate Loading Systems as the specialist in the development, manufacturing, installation and maintenance of industrial doors and dock equipment.

A development to be proud of! Absolutely. But Loading Systems wants to achieve much more!

A new way forward

CEOs (and twin brothers!) Ronald and Harald van Wijk have therefore chosen to embark on a new way forward:

"For years we were happy with moderate 'double digit' growth. It prevented growth spurts and attacks on our cash flow. However, with a good organisational foundation and great staff, we don't think this is good enough anymore. We want to be a leader in the industry!”

Loading Systems has therefore considerably adjusted its ambitions in the current multi-year plan, with a doubling of production numbers and, of course, sales performance.

The growth is visible in the company. Customers and partners see the clear focus and sense the good rapport with customers at the same time. Employees work with modern, company-wide IT systems that would not be out of place in large multinational companies. Loading Systems is clearly taking steps!

How so?

Loading Systems has become the ‘One-Stop-Shop’ in the market. Multiple sales channels provide enormous geographical coverage and can therefore meet the needs of various customer groups. The company also puts the customer first with expert advice, reliable products and high-quality maintenance.

That is why Loading Systems invests in:

An innovative product range

Loading Systems is always striving to improve its offering in order to serve its customers even better. The PowerLock 505NG automatic truck locking system and the Van dock levellers for retailers are excellent examples of this.

But Loading Systems also shows its responsibility towards the environment. One of the big polluters was the spraying department, which used a lot of volatile substances, with the accompanying emissions. By starting to use powder coating, emissions have been reduced to an absolute minimum! All the powder and any residue are completely reused and the quality of the product is even better. A powder-coated product remains rust-free even after a 1,000-hour test in a brine bath! Is that not innovation?

SLMF+ for improved process efficiency

Single Logistics Multi Finance is a solution where the entire supply chain of all companies is seen as one, without compromising the administrative independence of these companies. Loading Systems has linked a complete customer engagement programme to this. SLMF+ makes the process much more efficient and makes data a great deal easier to access and manage for the customer. For instance, work orders, invoices and drawings are available on the customer homepage. An essential contribution to making life easier for the customer!

Quantum Leap Programmes

If you improve processes, you can make a profit. Profit in time, quality, and money… and that is a priority, because that's how you can serve the customer better.

Loading Systems has therefore started two Quantum Leap programmes to eliminate disruptive factors. The programme for the Plants (production companies) is designed to double production capacity. Quantum Leap for the LSOs is aimed at being able to sell that double number of products.

Higher automation

Doubling the production number requires a high degree of automation. An additional production site, different machines and new robot lines will result in significant production gains and thus cost reductions. This gives the customer a price advantage and Loading Systems the possibility to develop into becoming the cost leader in the market.

New marketing campaigns

With increased production, constant quality and competitive prices, Loading Systems is ready to conquer the world! And everyone should know about it. From a commercial point of view, Loading Systems also goes the extra mile with large marketing campaigns reaching tens of thousands of potential customers and users.

Investing in coronavirus times

So, there are big plans, for which the preparatory steps have already taken place over recent years. However, it was precisely on the threshold of this next phase; where the real investments came into play, that coronavirus struck. What to do now then? Should Loading Systems continue with such ambitious plans, with all the associated investments, when there is uncertainty on so many levels?

Ronald and Harald van Wijk were not daunted:

"The most successful companies come out of a crisis stronger. We have that confidence, too. In addition, we are fortunate that in recent years we have been focusing more on recession-proof industries such as food - which is now serving us very well. And the success of our innovative Van-dock leveller comes as a fantastic support. This is our time!”

Top innovation at the right time

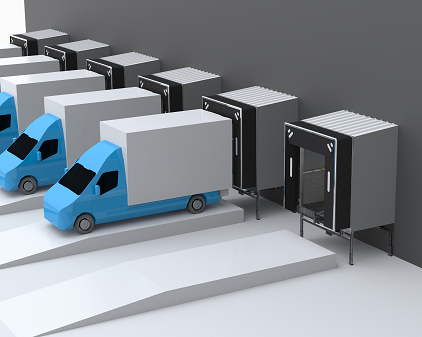

Loading Systems has developed the innovative Van-dock leveller with an eye on the annually growing e-business and the increase of vans in the logistic process. Charging stations in distribution centres are designed for trucks and trailers, but with increasing demand on home deliveries there is also a need for a suitable charging system for delivery vans.

With the Van-dock leveller, retailers can optimise their logistics process and load and unload their delivery vehicles efficiently and safely. And that has turned out to be a direct hit, especially at this moment in time. The coronavirus has created an explosive growth in e-business, and with it a great need for the innovative and unique loading solutions Loading Systems can offer!

Heading into the future with confidence

That shows once again that, as a company, you must be ahead of the game and not standing still. Even in uncertain times - or precisely in uncertain times - you must be flexible, adaptable and continue to develop. The trick is to come out of a crisis stronger than you went in. And Loading Systems has every confidence in being able to do so.

They are ready for a different future!

Smart loading and unloading for retailers

The online retail business is a highly competitive market. Service and delivery must be a smooth logistical operation to satisfy the customer. Loading Systems has therefore developed innovative loading solutions for delivery vans.

The delivery vehicle parks at the dock with the doors closed. The doors are opened and the Van-dock leveller is easily positioned in the vehicle with a control box. Then the vehicle can be loaded safely. Even small internal transport solutions can be driven into the truck!

If there is no room for a separate loading bay for vans, the Combi-dock leveller offers a solution. This dock leveller has a segmented flap, allowing it to be used for unloading a lorry as well as delivery vehicles. When needed, the mode on the loading ramp can be adjusted to load vans.

Loading Systems loading solutions enable retailers to load and unload their delivery vehicles in a smart manner. An essential step towards an optimal logistics process!

Would you like to know more about these and other innovative Loading Systems products?

Please e-mail: info@loading-systems.com or give us a call.